Configuration of controllers is performed with a series of graphical user interfaces. The Process Control Framework includes configuration screens for the following:

- Alarm Component

- Parameter Component – Used to store parameters for tools, parts, etc.

- State Component – Used to store the state of tools, reticles, etc.

- Log Component – Log of information from the controller.

- Sequencer Component – This includes control algorithms and business logic

The configuration screens also handle configuration management. This includes maintaining the state of each controller and its one or more versions that may exist in the system. As controller versions are approved, activated and removed from the system, each event is logged to the system log and is viewable through the log component. This provides an audit trail of what version of the controller was running at a particular point in time.

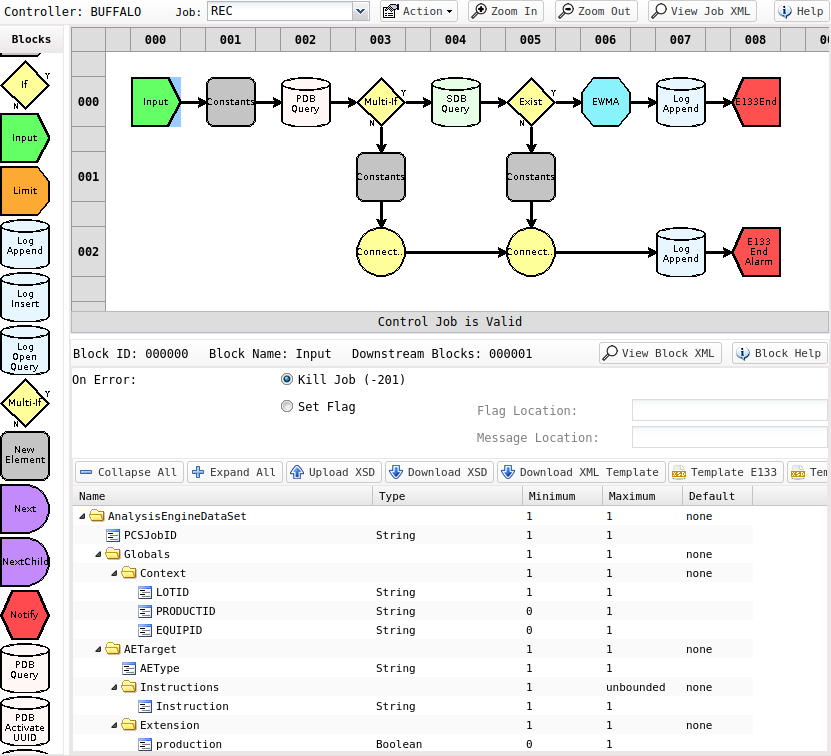

Below is the graphical user interface that a user will use to develop control algorithms and business logic. At this time over 90 blocks exist in the system to handle most the functionality required for a controller. Should a function not be available to solve a particular problem, custom blocks can be added to the system. This also allows for protection of customer intellectual property. Buffalo Automation is committed to providing a complete solution, and any new functionality will be promptly added to the product to support your needs:

Below is a list of blocks that allow for easy development and maintenance of controllers allowing for filtering of data, control equations and communications to/from external systems:

- Grubs Test for filtering outliers from a set of measurements

- Limit tests for detecting out-of-control and out-of-spec conditions

- Weighted moving average (WMA)

- Exponentially weighted moving average (EWMA)

- Western Electric rules

- CuSum

- FTP/rlogin/telnet

- Tibco